Our Expanded Metal products are commonly manufactured from the following alloys:

| Mild Steel | DD11 Hot Rolled to BS EN 10111: 2008 and Cold Reduced to BS EN 10130: 2006. Larger Mild Steel expanded metals can be Hot Dip Galvanized after manufacture to BS EN 1461. |

| Aluminium | Commercial Grade 1050 H14, Grade 5005, 55HX or J57S-UP for anodising & Grade 5251 for marine environments. |

| Pre-Galv Steel | DX51D + Z to BS EN 10346: 2015. |

| Stainless Steel | 304L (EN 1.4301), 316L (EN 1.4401) & 430 (EN 1.4016). |

| Copper | Grade C101 half hard. |

| Brass | Grade CZ106-0 soft. |

| Titanium | Grade 1 ASTM B265. Other specialist alloys and variants of the above materials can be processed into expanded metal products. Please ask for additional information. |

| Finishes | Our expanded metals can be powder coated to any colour you desire. We work closely with a number of expert painting companies who can paint to the RAL colour of your choice. Painting technology has improved rapidly in recent years and we are now able to supply painted mesh that looks and performs like an architectural anodised finish but at a fraction of the cost. The advantage of this finishing option is that colour consistency is guaranteed whereas there can be colour and shade variations when a traditional anodised finish is applied. This variation is caused by raw material inconsistency rather than the anodising process itself. By physically painting the mesh the chance of undesirable variation is eradicated. Additional information is available on 0800 999 2089. |

There are two types of expanded metal.

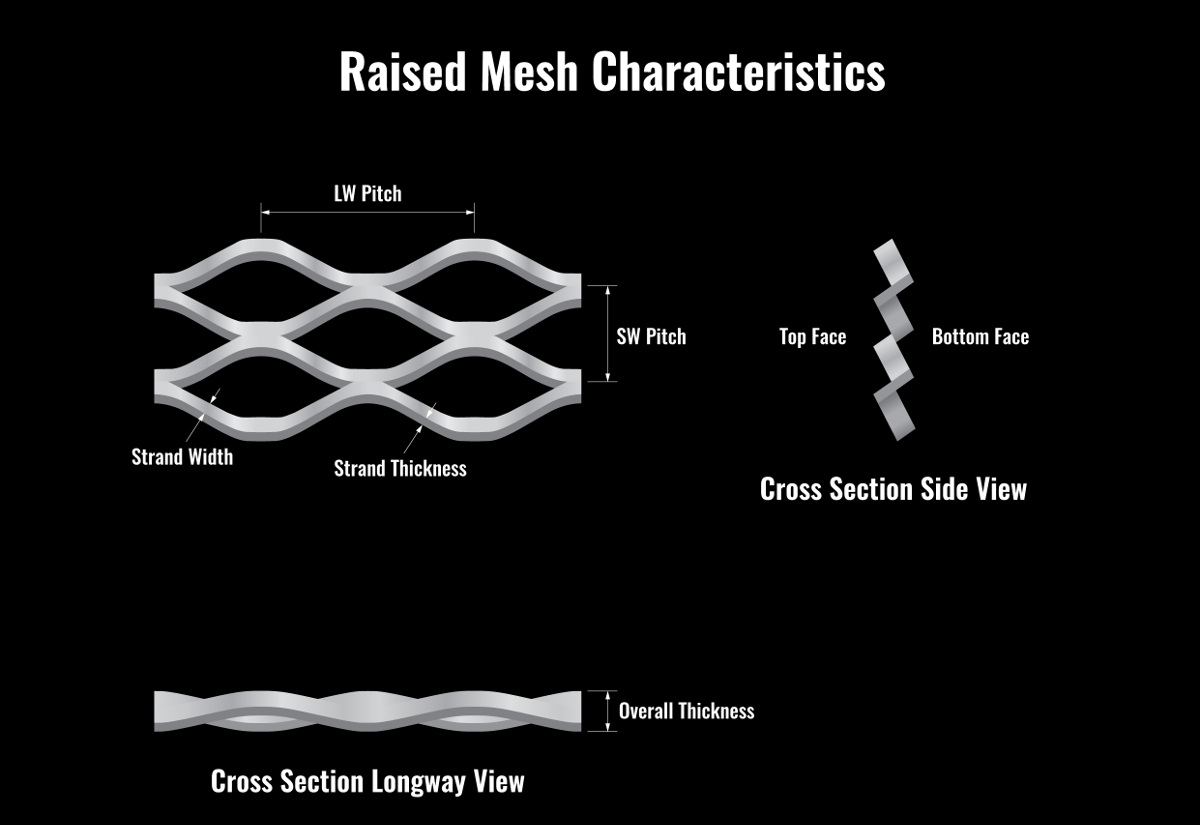

Raised mesh is unchanged from the expanding process where the individual strands are set at an angle to the plane of the sheet which results in a superior strength to weight ratio, enhanced sheet rigidity, good anti-slip properties and an increase in overall thickness of the original raw material sheet due to the angled strands.

Raised mesh is measured from the centre of one mesh to the centre of the adjacent mesh, this is referred to as the LW and SW Pitch as shown below.

Walkway mesh is described in the same manner as raised mesh.

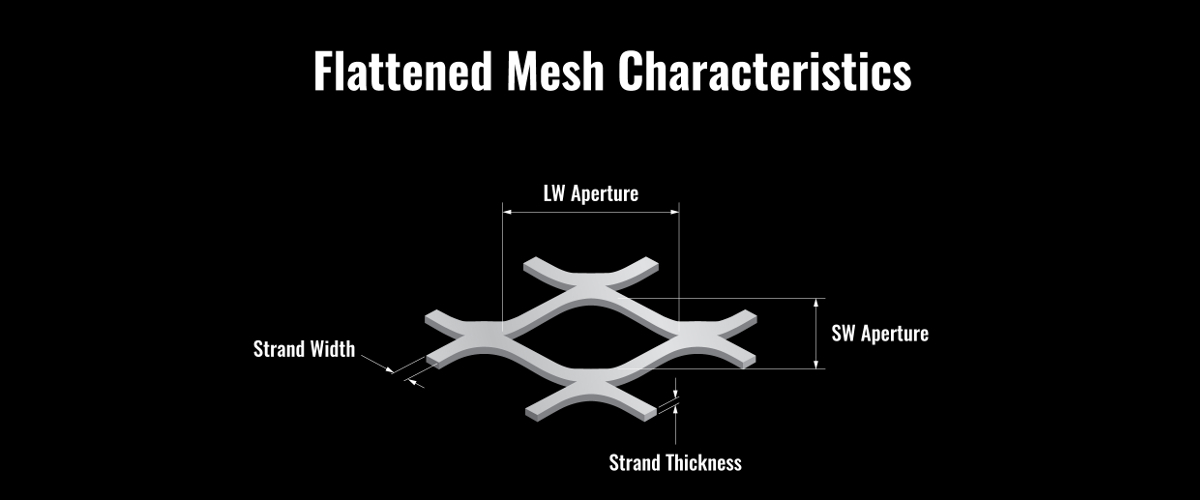

Flattened mesh is simply a raised mesh which is passed through heavy duty pressurised metal rolls to create a mesh with a flat surface to the sheet. Flattened mesh is generally processed to the same thickness as the original raw material or just below that base thickness. Flattened mesh is desirable where a lower overall thickness is desirable or if a flat surface is required to have greater surface area for example, when welding into a frame.

Flattened mesh is measured from the internal opening of the diamond, this is referred to as the LW and SW Aperture as shown below.

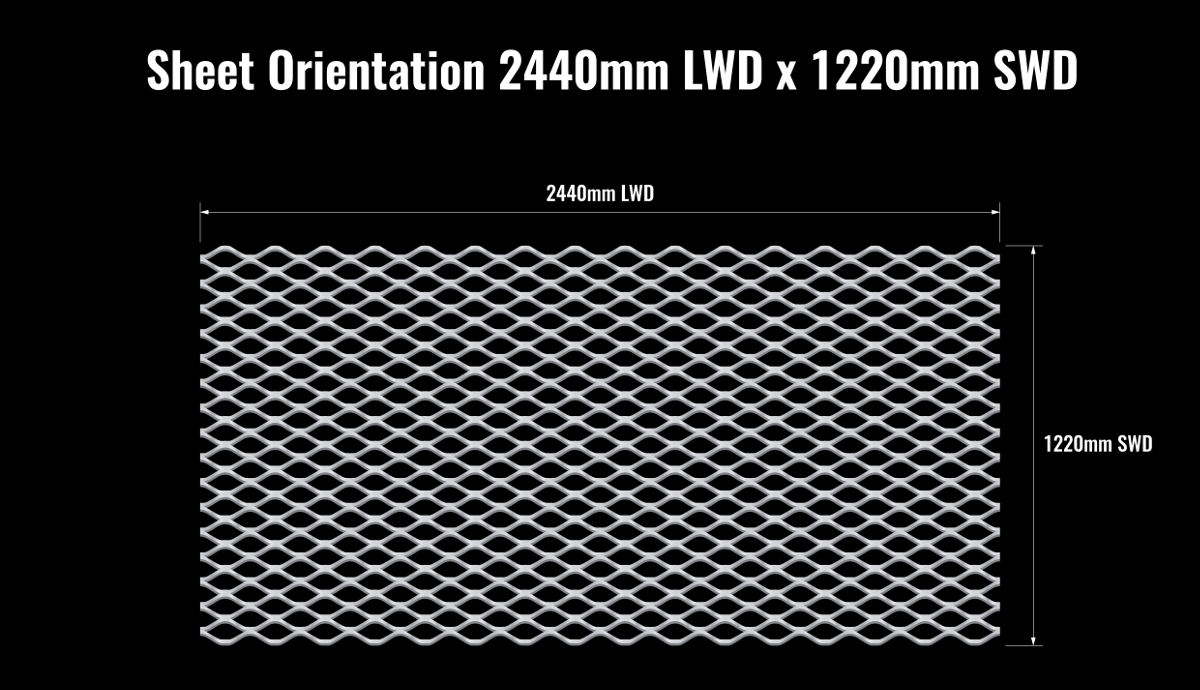

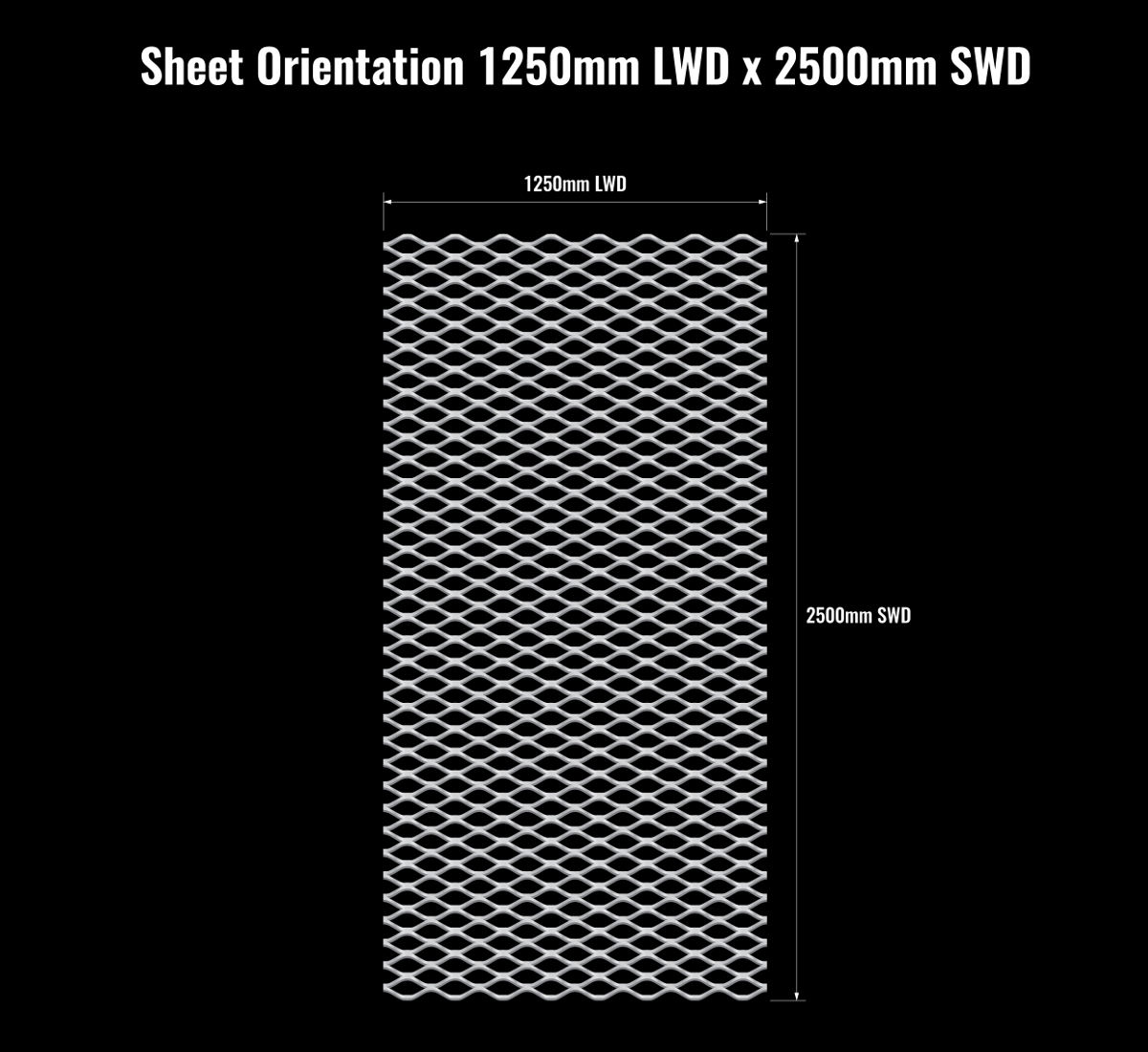

Expanded metal is available in a wide variety of sheet sizes. The items shown on our website are a guide to the standard items we manufacture as standard stock items.

The sheet size is descried as LWD and SWD (LW and SW Dimension). The standard sheet sizes are 2440mm LWD x 1220mm SWD and 1250mm LWD x 2500mm SWD as illustrated here.

Stock sheets are manufactured to a nominal plus tolerance and are likely to be delivered slightly oversize. If exact sizes are required we recommend this be discussed at the time of order.

It is possible to produce other sizes, please contact us for more details.

We offer a custom manufacturing service where bespoke specifications and sheet sizes can be made to suit your individual needs. This may be a variation to the mesh specification to enhance its performance or to ship the material to you in cut to size panels or large format sheets.

By purchasing cut to size sheets you will save valuable time and money within your own production environment by being able to use our expanded metal sheets which are cut to agreed tolerances straight off the pallet with no need for additional cutting. Likewise, there may be advantages for you to buy LARGE FORMAT XXL sheets that are produced in sheet sizes that are greater than those shown on our website.

We offer raised mesh, flattened mesh and walkway mesh in Large Format XXL sheets. Please call our team on 0800 999 2089 to discuss your individual requirements.

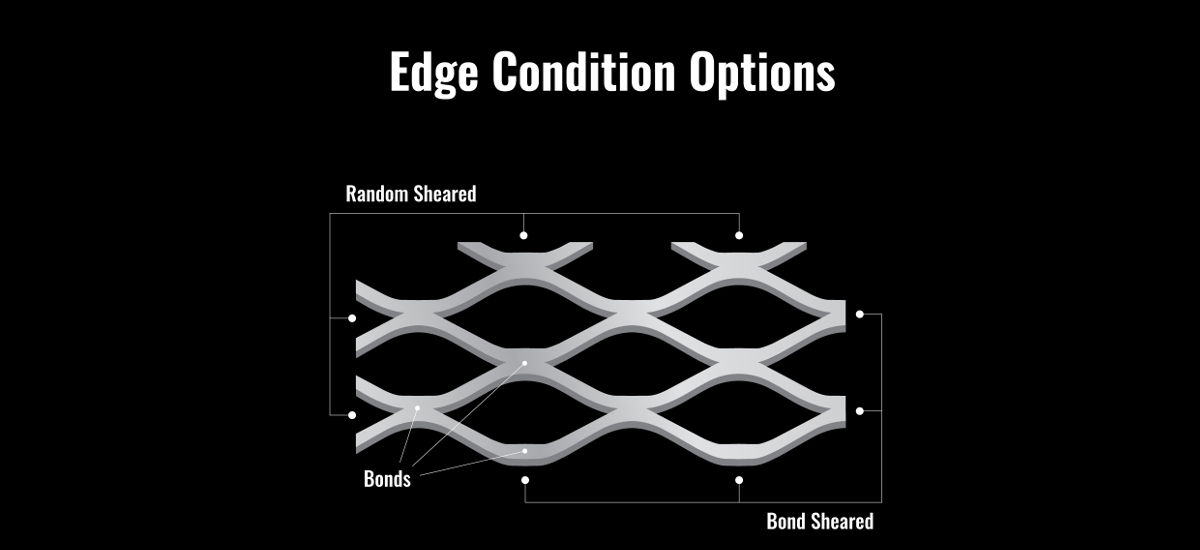

Cut to size sheets are supplied in a random sheared condition as standard. This is where the cuts are randomly positioned which results in open meshes on the cut edge of the sheet. Certain products may be cut to size with complete meshes on one or more edges, this is referred to as Bond Sheared, please notify us if your product needs bond sheared edges as this is a slower process and will need proper planning to ensure your requirements can be accommodated.

All our meshes are capable of being supplied in a cut to size finish, the majority being cut in-house on our guillotines. 6mm thick walkway mesh (12-99WR) and certain designer meshes cannot be cut on a conventional metal guillotine so would require cutting by a sub-contract water jet cutting service. Please ask for more details.

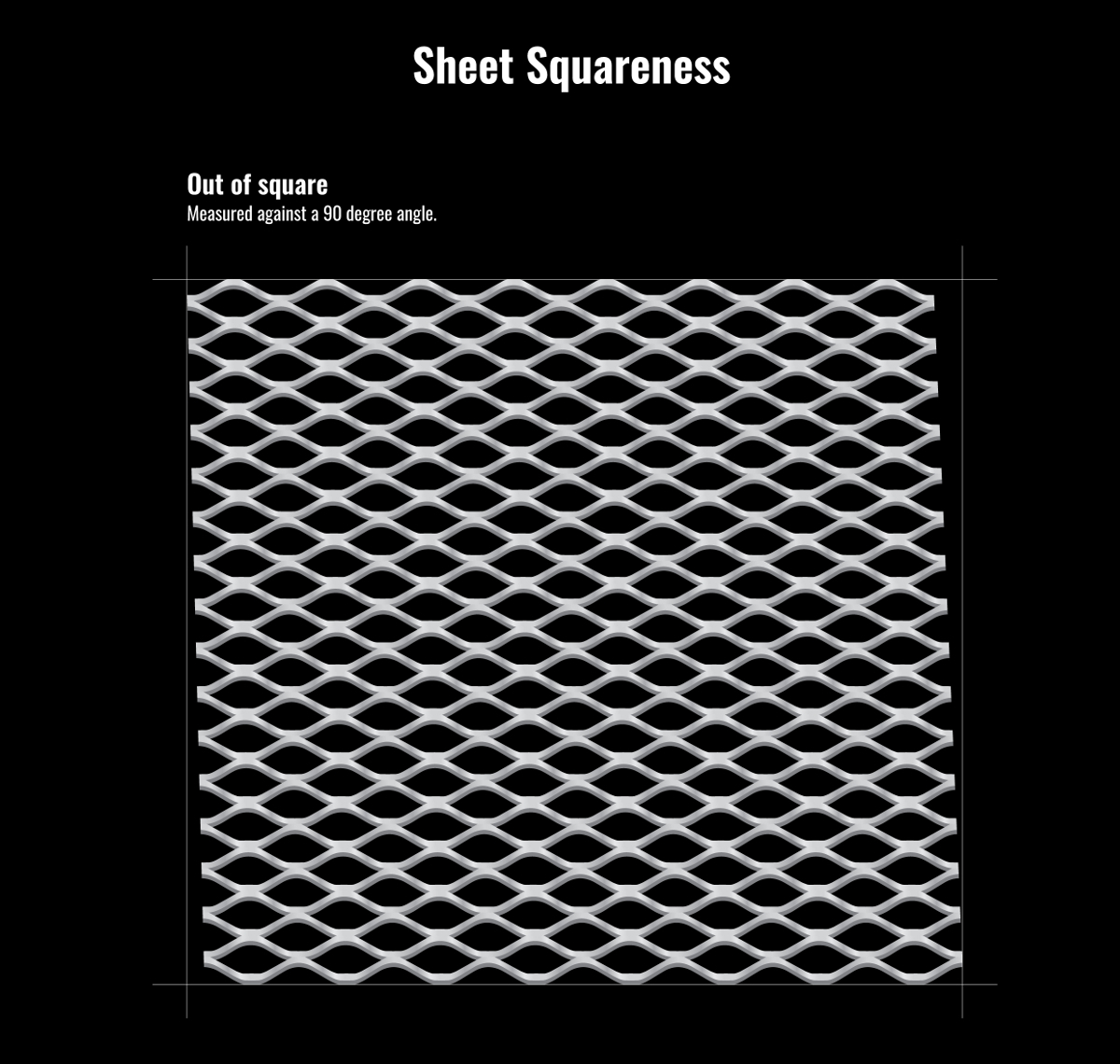

The benefit of sheared panels is not only dimensional accuracy and close tolerances but the shearing process ensures sheet squareness.

Expanded Metal which is machine run is not guaranteed to be perfectly square. The only way of creating sheets that are reliably square is to cut them after expanding. The illustration below shows how ‘stock’ mesh can be out of square, cutting to size is a reliable and quick way of overcoming this.

It is possible to introduce production controls for certain products at the planning stage to overcome the issue of squareness. Certain designer products can be machine run with very tight squareness and dimensional tolerances so please talk to us to discuss the specific needs for your project.

We are available to discuss all aspects of your requirement, call our experienced team on 0800 999 2089.

Metal Mesh UK Limited, Reet House, Keytec East Business Park, Pershore, Worcestershire, WR10 2NX.

Tel: Freefone 0800 999 2089 / 01386 555 500 Fax: 01386 555 200.

Email: sales@metal-mesh.co.uk. Skype: metal_mesh_uk.

Company reg: 06582396. ©Metal-Mesh UK Limited, 2009-2025 All Rights Reserved.